Li Qiang 1 Chen Yong Guang 1 Wu Zhi Hong 2 Huang Yong 3 Shi Jian 3

1. Haishen Electromechanical General Plant (Xiangshan), Ningbo 315718, Zhejiang Province;

Hangzhou Liqun Environmental Protection Paper Co., Ltd. (Zhejiang Hangzhou 310018);

3 Fujian Jinmin reconstituted tobacco Development Co., Ltd. (Luoyuan, Fujian)

Abstract With the development of domestic paper-making reconstituted tobacco technology, higher requirements are put forward for the solid-liquid separation equipment used in various process points with different physical properties, such as tobacco stem and tobacco powder. This paper introduces the application of centrifuge in the treatment of tobacco powder soaking solution. Practice shows that the centrifugal machine has certain technology in terms of separation dryness, treatment capacity and liquid purity Advantages.

Key words papermaking reconstituted tobacco lw520eb centrifuge

1 Overview

The paper-making process of reconstituting tobacco leaves is to produce raw materials for cigarette enterprises by using the technical principles of papermaking industry for reference, through the reorganization and processing of tobacco stem, tobacco powder (tobacco leaf fragments) and other materials. The screw extruder used in the past as a solid-liquid separation equipment has some defects, such as incomplete solid-liquid separation, unstable outlet material dryness, difficult internal cleaning and cleaning, large loss of fiber material and low purity of extraction liquid, which has been gradually replaced by centrifuge in recent years. Taking lw520eb centrifuge as an example, this paper introduces the application of centrifuge in tobacco dust treatment in detail The centrifuge has certain technical advantages in terms of treatment capacity, treatment effect (dryness, liquid cleanliness) and automation degree, which is worthy of promotion in the industry.

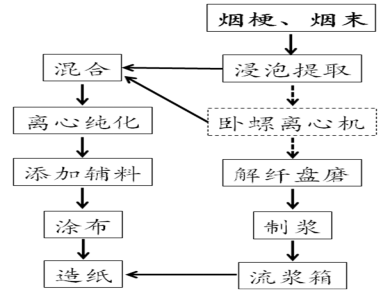

2. Process flow

The tobacco dust is soaked in 60-80 ℃ for 60 minutes and then separated into a centrifuge for solid-liquid separation. The separated slag phase is used for pulping and papermaking to make sheet base. The liquid phase is immersed in the sheet base after being concentrated, and the sheet base is dried and cut into tobacco flakes.

Analysis of main configuration, technical parameters, working principle, technical characteristics and separation effect of 3 centrifuge

3.1 main structure, technical parameters, working principle and composition of electrical system of horizontal screw centrifuge

3.1.1 main structure of centrifuge

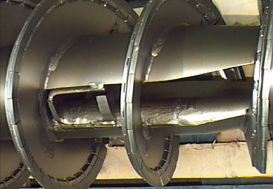

Lw520eb centrifuge is composed of main and auxiliary motor, reducer, screw body, drum, main bearing, frame, hood and transmission device.

3.1.2 main technical parameters of centrifuge

Technical parameter | Technical index |

mm | 520 |

r/min | 3200 |

G | 2980 |

r/min | 3000 |

kw | 55 |

kw | 18.5 |

3.1.3 working principle

The soaked tobacco stem or tobacco powder soaking liquid enters into the drum through the feeding pipe and the screw outlet, and under the action of centrifugal force generated by high-speed rotation, The tobacco stem or tobacco residue with large specific gravity is deposited on the inner wall of the drum. The spiral blade that moves relative to the drum continuously scrapes off the residue deposited on the inner wall of the drum and pushes it out of the slag discharge port. The separated clear liquid flows out of the drum through the opening of the liquid layer regulating plate.

3.1.4 composition and characteristics of centrifuge electrical system

A stable and reliable centrifuge electrical control system is composed of programmable logic controller (PLC) as the core, color LCD touch screen with friendly interface as man-machine operation interface, double motor and double variable constant torque control with excellent energy saving. It adopts one key operation, and the initial operation parameters are set automatically. The whole process is in accordance with the prepared program Automatic operation, without human intervention, to achieve real automatic operation. In the process of feeding operation, constant torque and constant differential speed are used to adapt to the change of material concentration and flow rate, improve the adaptability of centrifuge to production process, ensure good sharing effect and stable operation state. It is a simple and complete control system.

3.2 centrifuge technical characteristics, treatment effect and treatment capacity analysis

3.2.1 technical features

(1) The key parts are designed with carbide and anti-wear technology of rotary drum

According to the material characteristics of flue gas mother liquor, the use of cemented carbide insert technology at the outlet and screw thrust surface of the drum can increase the service life by more than 1.5 times, greatly improving the stability and reliability of the machine; the inner wall of the drum body adopts the anti-wear strip structure, which can effectively prevent the abrasion of the inner wall of the drum, and is conducive to the better pushing out of the slag phase.

(2) Advanced BD buffer plate structure

The screw pusher adopts the international advanced buffer plate structure and combines the centrifugal technology with the extrusion technology. We apply this technology to the treatment of the mother liquor of tobacco powder. It can further compress the tobacco powder, so that the solid content of the treated tobacco powder is high, the treatment capacity is large, and the slag content of the liquid is low.

(3) Capture structure of floating objects

In view of the particularity of the material of the mother liquor, the helicoid is the most advanced FD board barrier used in China to block the foam particles and floatation in the clear liquid and discharge it from the solid discharge port. Note: FD plate barrier has been applied for national patent by Haishen Electromechanical General Plant (Xiangshan) on October 10, 2014, patent No.: zl2012200317380

(4) Unique vortex inlet design

The vortex structure is adopted to accelerate the material to enter the drum quickly, shorten the contact distance between the material and the liquid pool, reduce the disturbance of the feed on the formed solid separation, improve the processing capacity, and avoid the blockage in the screw and the locking of the feed pipe. The service life of spirochete is increased by surfacing WC Cemented Carbide at the material outlet.

(5) Large aspect ratio

The centrifuge adopts a large aspect ratio structure, which can increase the settling area of materials, prolong the residence time of materials in the drum, and improve the solid removal rate, which is the goal pursued by the separation technology industry.

(6) Variable pitch technology adopted

Increase processing capacity - "small, big capacity"

(7) It adopts double motor and double frequency conversion drive to save energy and electricity

The operation of the main / auxiliary motor adopts the main / auxiliary frequency conversion control. When the spiral lag occurs, the auxiliary motor is in the generator state when working, and the regenerated energy is sent to the DC bus of the auxiliary frequency converter. Because the DC bus of the main / auxiliary frequency converter is in parallel, the energy is used by the main motor through the main frequency converter. Compared with other differential control, it can save 15% energy and start smoothly.

(8) Advanced CIP automatic flushing program

In order to avoid the sediment accumulation after the centrifuge stops, which will cause the vibration of the next start-up, and prevent the sediment from fermenting inside the centrifuge and affecting the product quality, CIP washing process includes two parts: internal washing of the drum and external washing of the drum.

External washing of drum: equipped with industrial high-pressure nozzle, the external wall of drum, inner chamber of frame and inner chamber of hood can be effectively cleaned by spraying. The control program of the centrifugal machine for the external spray washing of the drum is relatively simple. Generally, the external spray system can be opened while flushing the inside of the drum.

Internal flushing of the drum: the flushing water enters into the drum of the centrifuge through the feed pipe of the centrifuge, and the accumulated material in the drum is continuously discharged from the drum under the driving of the screw. At the same time, the material ring formed by the centrifugal force of the accumulated material is constantly damaged through multiple start-up and shutdown operations, and the spiral blade and inner wall of the drum are also scoured by the water ring damage process during the shutdown process, The internal flushing of centrifuge is ensured.

3.2.2 treatment capacity and treatment effect analysis

(1) Parameters of treatment capacity

When the solid content of feed is 10-15%, the centrifuge capacity is 10-12m3 / h, the solid content of slag phase is 29-32%, and the solid content of clear liquid is less than 0.05%.

Separated slag phase

Separated liquid phase

3.2.3 factors affecting separation effect

(1) Influence of feeding and conveying mode on separation effect

There are two solutions to the problem that the volume expansion of tobacco powder (tobacco leaf) with larger diameter will affect the normal material transportation of centrifuge after soaking. One is to improve the structure of centrifuge, increase the diameter of feed pipe and redesign the screw body and drum components. The second solution is to use soaking without affecting the material properties It is a method of solid-liquid separation after being transported to the tobacco powder (leaf) cutting machine for cutting and then entering the centrifuge for solid-liquid separation.

(2) Influence of separation factor on separation effect of centrifuge

In theory, the higher the centrifuge speed is, the higher the separation factor will be, and the better the separation effect will be. However, when the separation factor is increased to a certain value, it will not only be meaningless, but also significantly increase the power loss of the centrifuge. Therefore, the speed adjustment will directly affect the processing capacity and treatment effect of the centrifuge in unit time.

(3) The influence of differential speed on separation effect

When the differential velocity is large, the spiral discharging speed is fast, but the moisture content in the solid phase increases; when the differential speed is small, the spiral discharging speed is slow, and the water content of the solid phase after separation is reduced. As the adjustment of differential speed is relatively simple, it is only necessary to reduce or increase the frequency of the auxiliary frequency converter to complete the adjustment.

(4) Effect of liquid layer depth on separation efficiency

The closer the opening of the liquid layer regulating plate (sheet) is to the center of the drum, the deeper the liquid layer is, and vice versa; deepening the liquid layer will reduce the solid content of the liquid phase and increase the water content of the solid phase; if the liquid layer is lowered, the water content of the solid phase will be increased; otherwise, the opposite will happen.

(5) Influence of wear resistance of spirochete on separation effect

Therefore, due to the higher screw resistance of the sand and the exit of the blade, it is proposed that

It is required that the edge and surface of the spiral blade are made of replaceable tungsten carbide or sprayed to protect the whole length; the detachable hard alloy wear-resistant tile is used at the screw outlet to effectively prevent sand particles from wearing the screw outlet.

。

Feasibility analysis of using horizontal screw extruder instead of 4

4.1 the liquid from the screw extruder still contains fine particles, while the liquid from the horizontal centrifuge almost does not.

4.2 the moisture content in the solid extruded by the screw extruder is 72%, and the moisture content in the solid from the horizontal centrifuge can also be less than 72%.

4.3 the price of screw extruder is much higher than that of horizontal centrifuge with the same processing capacity.

4.4 in the original process, there is still a centrifuge behind the screw extruder, while the liquid treated by the horizontal centrifuge does not need to be processed by the centrifuge, so the investment can be saved.

5 Conclusion

The separation practice in Hangzhou Liqun, Fujian Jinmin, Taicang Haiyan, Jiangsu Xinyuan and other well-known domestic reconstituted tobacco manufacturers has proved that the horizontal screw centrifuge is an ideal choice in terms of separation dryness, treatment capacity, liquid purity, operation cost, centrifuge stability and reliability.

reference

Li Zhenwei. A new integrated sludge dewatering unit with horizontal screw centrifuge. China water supply and drainage, 2003. (04): 16-20

Li Qiang. Application of centrifuge in cyanobacteria treatment. Water industry market, 2012 (15): 12-15

3. Centrifuge selection manual. Beijing: Chemical Industry Press, 2003